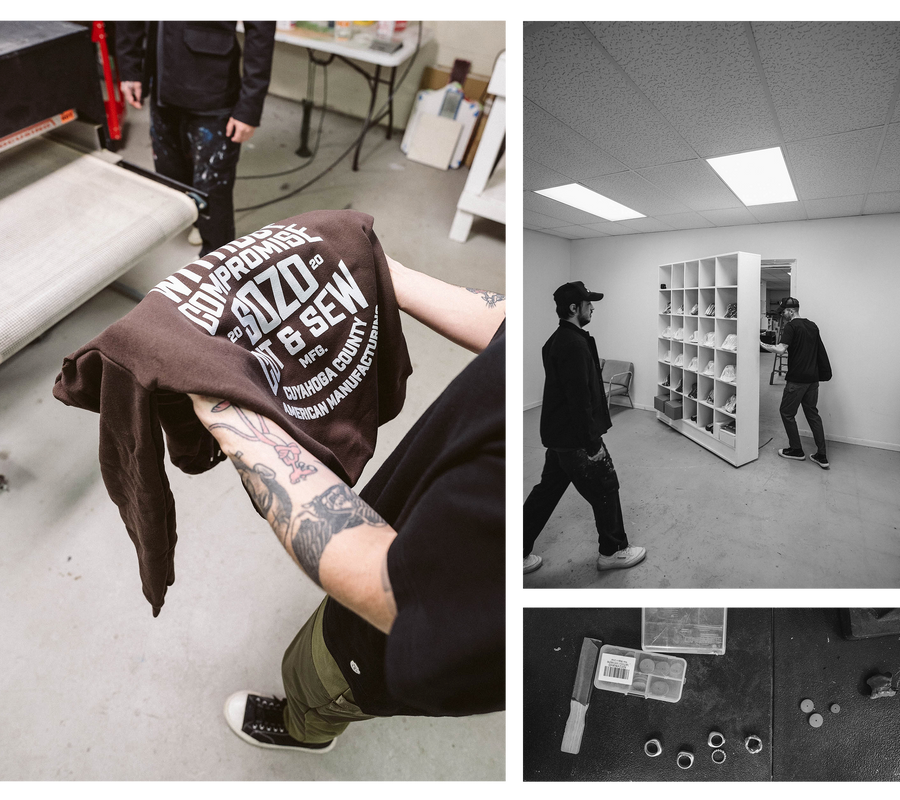

Maker Feature No. 006

IN THE ALLEY

At its core, Sozo is a brand that celebrates artists, entrepreneurs, innovators, and of course, makers. We do this by supporting their work and telling their stories through our SOZO Maker Features.

Ben Soltis, Co-Owner of In The Alley Print Shop, sat down with us for an interview conducted by our team to discuss what being an American maker means to him. Read his full interview and shop his look below.

Tell us a little bit about yourself.

My name is Ben Soltis. I’ve spent most of my life in Northeast Ohio, and I run a multi-disciplinary creative agency called 'In The Alley' with my business partner Aaron Boles.

Was starting your own business always a passion of yours? If not, how did you come into it and at what age?

I have always thought I would start my own business, even my family knew I’d be an entrepreneur. I remember being a little kid and I would look at everything in my house, add it up, and think of what the total would be. I don’t know why, but I always used to think of things in that type of way.

I've also always been into the arts. Especially growing up in the age where social media has become this huge thing, everything kind of changed. So, I think the combination of those two things really led me in a different direction.

Every year after high school I applied to schools and visited them. I even took some classes; but I never fully committed to it. That went on for about four or five years. After the fourth year of me saying, “alright, I don’t think I’m going to do this,” that was when I fully committed to starting my own brand and my own company.

Another part of all of this was when I was 18 and getting ready to go to college. I had a few friends who were diving into the creative industry and finding some success. I was watching a few people work with some big companies and whether it was Asics, Nike, or whoever, I saw them using another path to get into this industry. I saw it from a different angle. It was around that time I started seeing it as a possibility.

How would you describe your philosophy?

I think we’re still writing that and constantly figuring out what that is. The biggest thing that has gotten us to where we are is our network. Being really good to the people around us has really helped bring us more work and success.

Regardless of whatever we’ve had going on, this has always been a people business from the very beginning. We got into this industry because we’ve dealt with a lot of people and had lots of bad experiences, and we’ve heard about these same experiences from a lot of our peers too. We just felt that there was a gap in the market for helping people see their ideas through, and we felt that we’d be able to fill it. When Covid came around, we thought: let’s take advantage of this time that we have off and create something for ourselves.

What are the mediums you use most often and what does your creative process look like?

The best way I can describe what we do is that we’re like a swiss army knife in terms of production spaces or creative agencies. We know a little bit about a lot of different things, but we’ve also done a deep dive into some and learned a lot about the best ways to do them.

Nowadays we operate client to client. For example, we might be dealing with a company like Moncler that needs something printed on a specialty good. Or, we have a friend that makes clothing and they need something cast in metal. Or, maybe, it’s just a company that needs help with 3D or graphic design. Everything we do is very conversational and people based. We like to be a utility for other businesses.

When I first came into the creative industry I remember hearing someone say, “get used to being used.” Meaning, it’s a good thing to be used because if you can’t be used then you’re useless. I know that could be taken as a bad thing, but as I’ve grown into a creative my thing has become: how can I be the most useful to all of these people that I come into contact with? If you have this network and you see all of these people doing cool things, how can you contribute? How can you be used?

Once we figured that out, we started looking around and tried to find what was available to us and what wasn’t. What are the things that people are trying to figure out how to do? We thought if we could find a way to figure out how to do one of those things then that’d be the service we’d try to provide.

Who’s trying to find someone that can screen print? Who’s trying to find someone to make jewelry? Then, we’d find a way to cover them.

Describe a moment when you failed. What did you do and what did you learn about yourself?

First off, I have so many failures. Even just from the past week.

The biggest thing I’ve learned is that failures are a part of the process, and you can’t trip over them too much. We almost expect things to go wrong. We overbuy, we give ourselves extra time; it’s all a part of the process.

When we started bringing employees on, that was something we had to be super aware of. You can’t be mad at people for learning. Things are always going to go wrong. We’re constantly learning and growing. So, when something does go wrong, we just catch it as soon as it does and address it immediately.

Let’s say something comes up with a client… maybe… their whole order doesn’t get shipped. We’ll immediately let them know what’s going on so we can solve the problem, rather than letting it become something bigger than it is.

Instead of pointing out a specific failure, I’d say it’s been more about learning how to constantly deal with failures.

With SOZO’s mission to restore American craftsmanship, what does being an American maker mean to you?

The more that we do different types of projects, the more I’m starting to realize how important it is to certain people that everything stays here. I’m also learning that in a lot of creative industries, you get to a certain point where you start outsourcing things.

In the clothing industry, for one, you hear a lot about things being made overseas. So much, that it almost feels like that’s the only path. Like, you get to this point where you can make things overseas. You can make this pattern… send it out… it’ll get made… and sent back to you. But to me, that just sounds so backwards.

One of the first things that I learned from casting metals, which also goes hand-in-hand with what’s happening with 3D printing, is that these shoe companies are now able to 3D print their designs. So, let’s say someone designs a shoe and they want to show it to someone overseas. The designer can send them a file, it’ll print in under 24 hours and the people overseas can see that sample almost instantly.

The ability to make changes, and really just accessibility in general, has gotten better and easier. So, why would we be sending these things out when we have the ability to make them here?

The more that we’ve taken jobs in the production field, the more I’ve been thinking that we really are trying to bring manufacturing back to the United States. We’re showing people that we can create the same quality product, and that there really are people here that are willing and motivated to do it at every level. Whether it’s at a local level or if there’s a higher demand, it doesn’t need to be shipped out to get a higher quality product.

Another part of all of this is what we learned during Covid. When the borders were locked up you can’t always rely on someone else for a bulk of your business. If that’s what you’re doing, you should be able to do it here. If you’re not able to do it, then I feel like that’s a good place to start over and research what you’re working on and find new ways to get it to the public.